Using AI and automation to get to

market faster.

market faster.

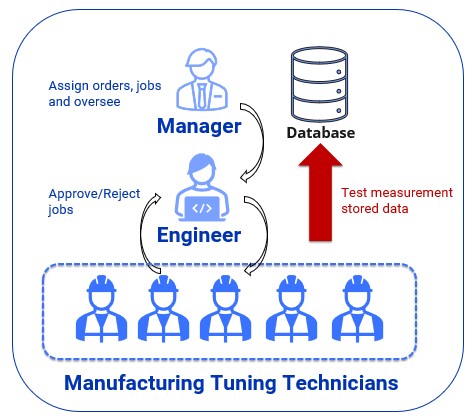

SynMatrix recently announced a computer-aided manufacturing workflow system to support high volume RF filter production. As manufacturers ramp up production volumes to new highs, managing the projects and order requests will be a steep challenge for operations.

SynMatrix's workflow system aims to help manufacturers by providing an all-in-one solution to manage project requests and orders, provide a channel to manage communications between engineering and technicians, and provide a system for tuning data traceability for quality control.

Here are some of the key features included in the system:

To learn more or request a demo, contact us at info@synmatrixtech.com.

Get the latest and greatest from our blog straight to your inbox.